The PFC Hydraulic Oil Filter Cart was designed by a Certified Lubrication Specialist. This particular model is equiped with a pneumatic pump, which is ideal for situations where access to an electrical outlet is limited (such as field work), or where electricity/sparks are prohibited. These types of portable filter carts are ideal for high-viscosity lubrication and hydraulic oil filtration. They can be used for filtering new fluids during transfer and replenishment, as well as filtering fluids that are currently in service. This two-stage filtration system offers the advantage of removing both particulates and water contamination.

Our PFC Filter Cart will help protect your fluid systems against failure due to poor oil quality. Using the PFC Filter Cart will allow you to meet or exceed your target oil cleanliness codes per ISO 4406.

Our PFC Pneumatic Filter Cart utilizes a positive-displacement pneumatic pump that transfers fluids by movement of diaphragms driven by compressed air. It incorporates a pulsation dampener which acts as an air cushion and automatically adjusts to the pressure change and absorb any pulsation.

The PFC Hydraulic Oil Filter Cart is designed with the operator in mind. It includes wand storage and a drip pan to minimize spillage. The 10″ pneumatic wheels provide shock absorption, quiet operation, and ease of rolling over rough terrain.

Downloads

PFC Pneumatic Filter Cart- BETA 1000 Rated Filter Elements per ISO 16889 Standards

- Water Removal Filter Elements

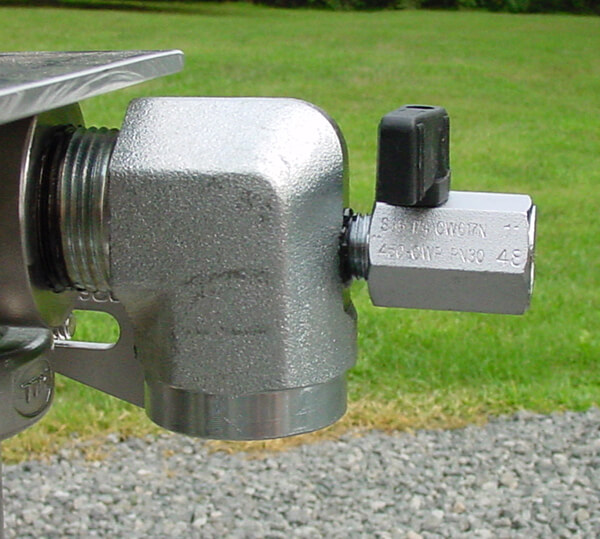

- Upstream and Downstream Oil Sampling Ports

- Pressure Gauge

- Condition Bulk Oil Before Use

- ISO Viscosity Range of ISO 22 to ISO 320

- Seamless Stainless Steel Tubing with JIC Fittings

- (2) Medium Pressure Hydraulic Hoses

- Pneumatic Pump – No Electricity Required

- Pulsation Dampener

- Stainless Steel Filter Housings

- Two-Stage Filtration

- Flow Rates Range from 3.4 GPM to 49 GPM (~13 LPM to ~185 LPM)

- Pump Specifications

- Self-Priming Pneumatic Driven Pump

- Variety of Bladder Materials Available for Every Application

- Material of Construction

- Assembly Frame: Lightweight Aluminum

- Inlet Suction Strainer for Pump Protection

- Tires: 10” Pneumatic (Puncture-Resistant)

- Filter Assembly: Stainless Steel

- Hoses: Medium Pressure Hydraulic

- Wands: 40” Stainless Steel

- Operating Temperature

- Nitrile (Buna-N): -40F to 150F

- Fluorocarbon (Viton)*: -15F to 200F

- *High Temperature/Phosphate Ester Design

- Hydraulic Oil

- Turbine Oil

- Lubrication Oil

- Gear Oil (ISO VG 220 ~ VG 320)

- Transformer Oil

- Diesel Fuel

- Phosphate Ester (Fyrquel EHC Fluid)

- Filter By-Pass (Transfer Pump)

- Inline Digital Particle Counter

- Flow Meter

- Spin-On Inlet Strainer

- Reservoir Holding Tank