Flow Rates: Flow Range of 1 GPM – 100 GPM (4 LPM -380 LPM)

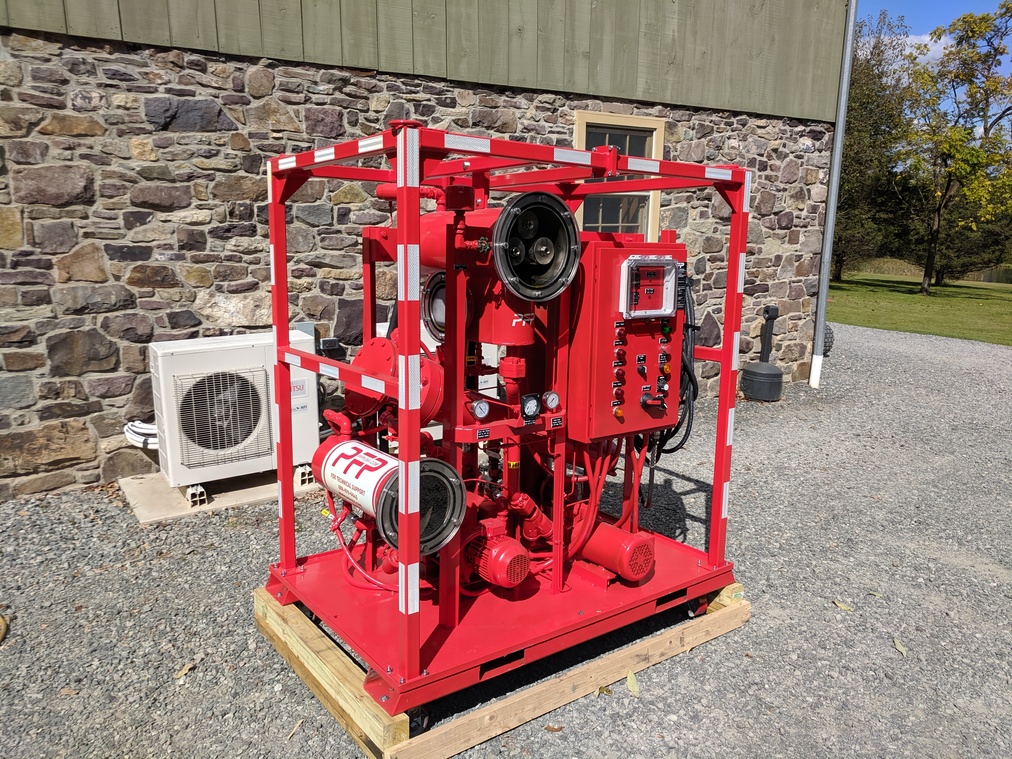

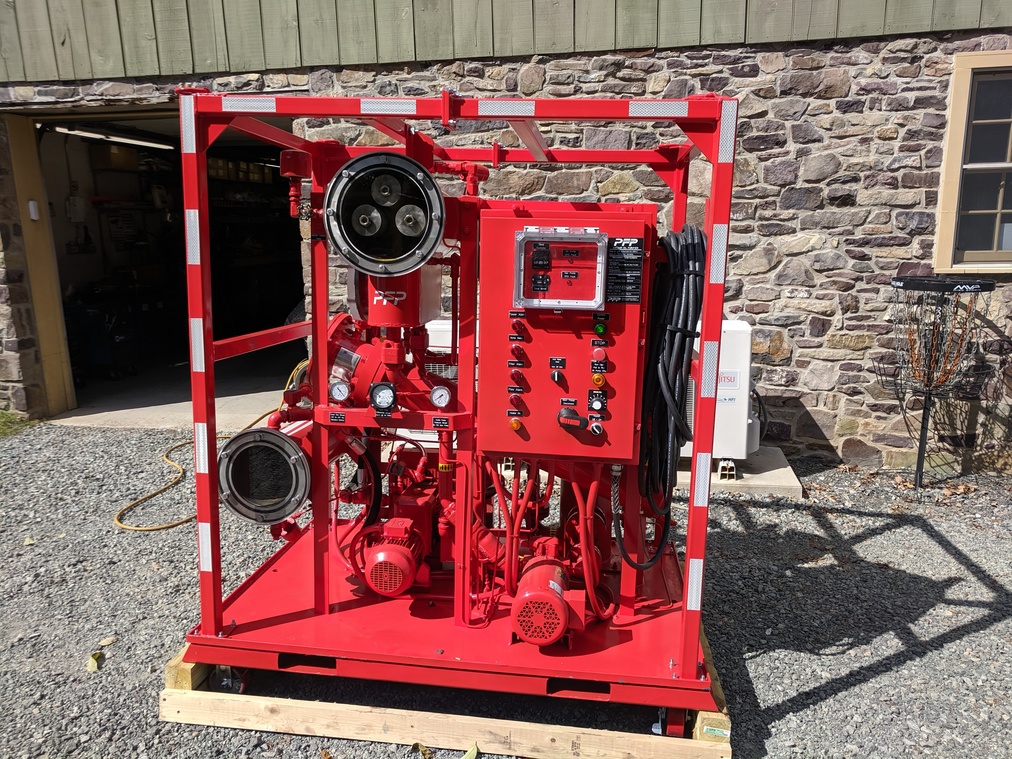

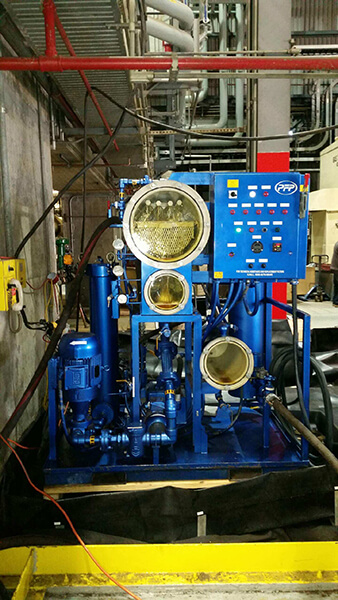

Here at Precision Filtration Products (PFP) we offer the most effective, durable, and user-friendly vacuum dehydrators on the market today. Our superior engineered design features maximize the water extraction rates from your oil. Utilizing top-quality components and workmanship ensure years of maintenance-free operation and performance.

Looking for a Oil Purification System? Check out our Vacuum Dehydrator Oil Purification System (VDOPS)! It has the ability to develop high-vacuum and high-flow speed for dissolved water and gas removal. The VDOPS has a high negative-head capacity and is flexible with design dimensions and process arrangement. We will listen to your needs, then customize a vacuum dehydration system to your specific application!

It has been well documented that there are harmful effects to the components on rotating equipment caused by particulate and moisture contamination in hydraulic and lubrication oils. End-users can dramatically increase the life of the critical wear components and in-turn minimize downtime and maximize profitability.

Downloads

VOP 20-GPM, NEMA 7, brochure Vacuum Dehydrator Application Data Sheet- Flow Range of 1 GPM – 100 GPM (4 LPM -380 LPM)

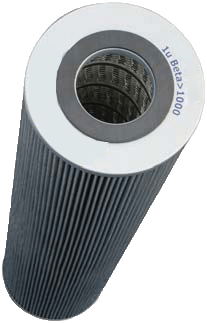

- BETA 1000 Rated Filter Elements per ISO 16889 Standards – ISO codes as low as 14/12/9

- Remove Free, Emulsified, and Dissolved Water - Achieve Overall Water Content As Low As 20 PPM In Multi-Pass

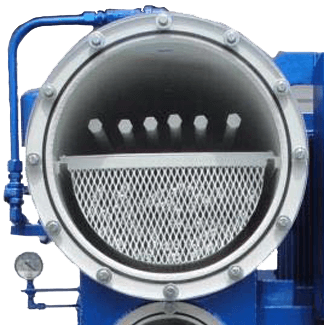

- Permanent Dispersion Media Inside Vacuum Tower – maximizes water extraction rates, and enables the system to operate effectively on high viscosity gear oils

- Variable Frequency Drive – Adjust Flow Rates to the Optimal Rate to enhance the overall performance

- Entrained Air and Gas Removal – Degassing via Vacuum Distillation

- Acid Removal – Can Be Equipped with Fullers Earth or Activated Alumina Cartridges to Neutralize Acid and Lower TAN

- Varnish Removal – Can Be Equipped with ION Charged Bonding Cartridges To Remove Insoluble Varnish

- Visually Monitor Fluid Condition through Plexiglass Windows

- Upstream and Downstream Oil Sampling Ports

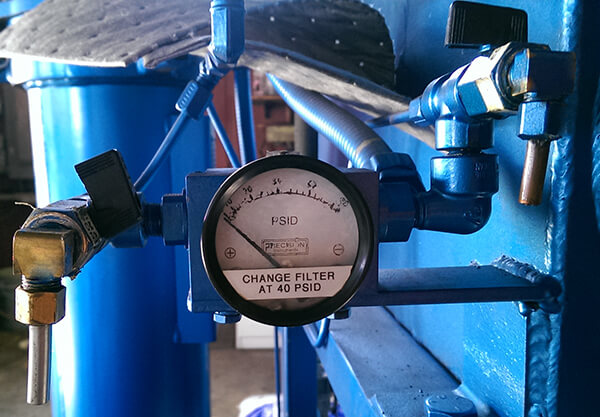

- Differential Pressure Gauge – Plugged Filter Indicator Light

- Low-Watt Density Heaters

- Dimension and Arrangement Design Flexibility

- Condensate Water Holding Tank

- PLC Control Start/Stop

- Flow Rates Range from 1 GPM to 100 GPM

- Electrical Service

- 3Phase/60Hz/480V

- Pump Specifications

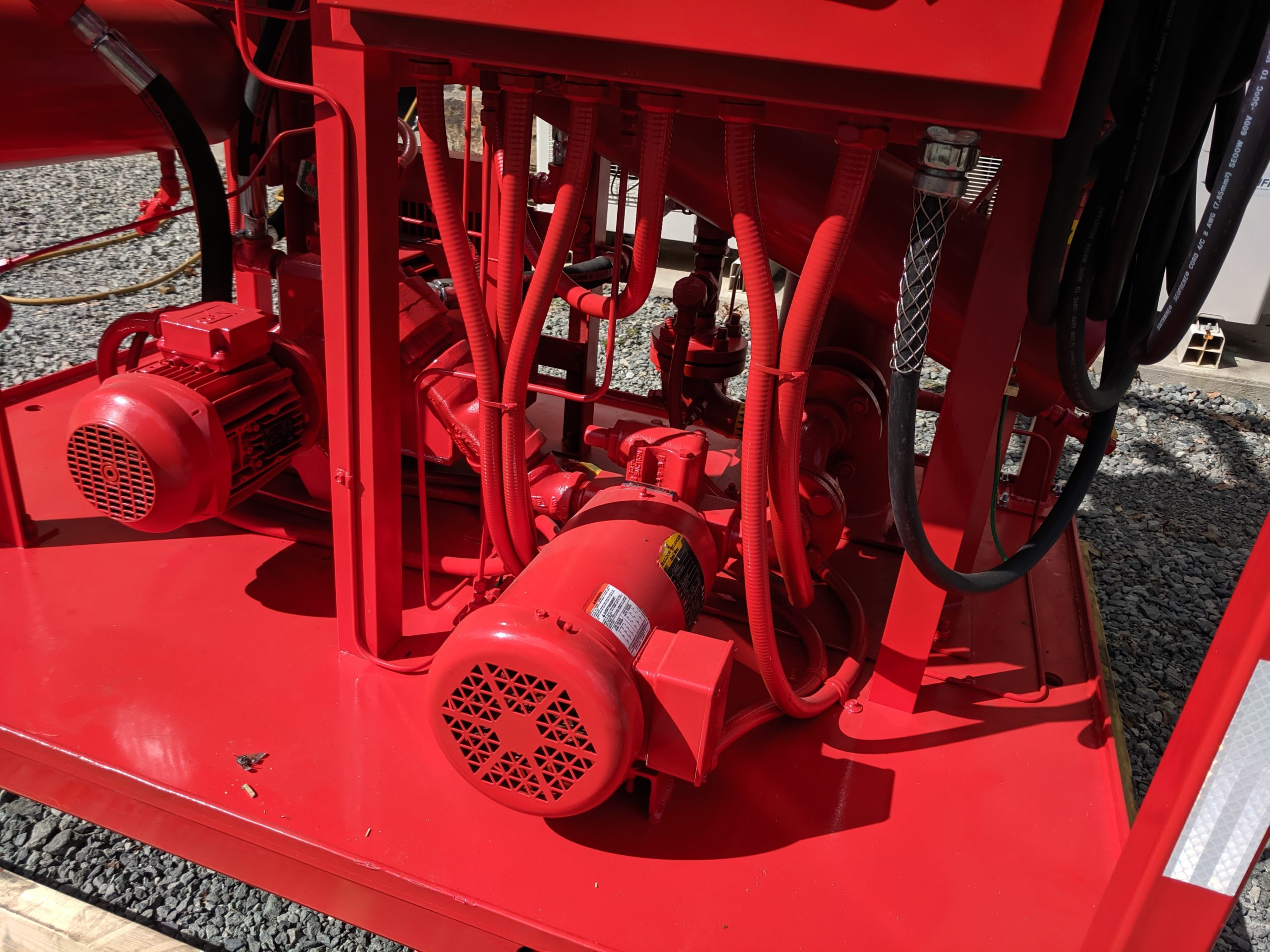

- Self-Priming Positive Displacement Gear Pump

- Internal Relief Valve Set at 100 PSI

- Claw-Style Vacuum Pump – pulls deeper vacuum, higher CFM, and requires less maintenance

- Motor Options

- Class 1 Explosion Proof

- 50 Hertz, 3 Phase

- Material of Construction

- Assembly Frame: Powder Coated Carbon Steel Platform

- Inlet Suction Strainer for Pump Protection

- Piping and Fittings – Carbon Steel

- Filter Housing – Powder Coated, Epoxy Lined, Carbon Steel

- Hoses: 20’ Medium Pressure Hydraulic

- Operating Temperature

- Nitrile (Buna-N): -40°F to 150°F

- Fluorocarbon (Viton)*: -15°F to 200°F

- High Temperature/Phosphate Ester Design

- Hydraulic Oil

- Turbine Oil

- Lubrication Oil

- Gear Oil (ISO VG 220 ~ VG 680)

- Transformer Oil

- Diesel Fuel

- Phosphate Ester (Fyrquel EHC Fluid)

- PAO Fluid

- Inline Digital Particle Counter

- Inline Digital Moisture Indicator

- NEMA 7 Explosion Proof Components

- Stainless Steel Wetted Parts

- 4-Point Lifting Lug Cage Structure

- Flow Rates Up to 200 GPM