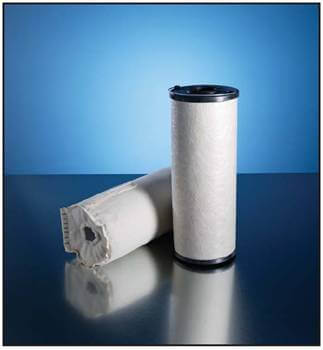

Clay Treaters are used in multiproduct pipeline installations, and wherever surfactant laden or discolored fuel is a problem. They can be configured to accept bags or canisters.

Clay treaters will continuously adsorb surfactants, color and additives from jet fuel when used with Facet replaceable clay elements. Housings are designed for easy servicing and low maintenance. All are built to ASME Code, Section VIII. Standard and optional accessories and connections are available to facilitate piping and installation requirements.

Looking for a temporary system, check out our Emergency Rental Page to see a list of our Clay Treaters available for short and long term rentals.

Materials of Construction

Carbon Steel

- Interior – Epoxy Coated

- Exterior – Prime Coated

Downloads

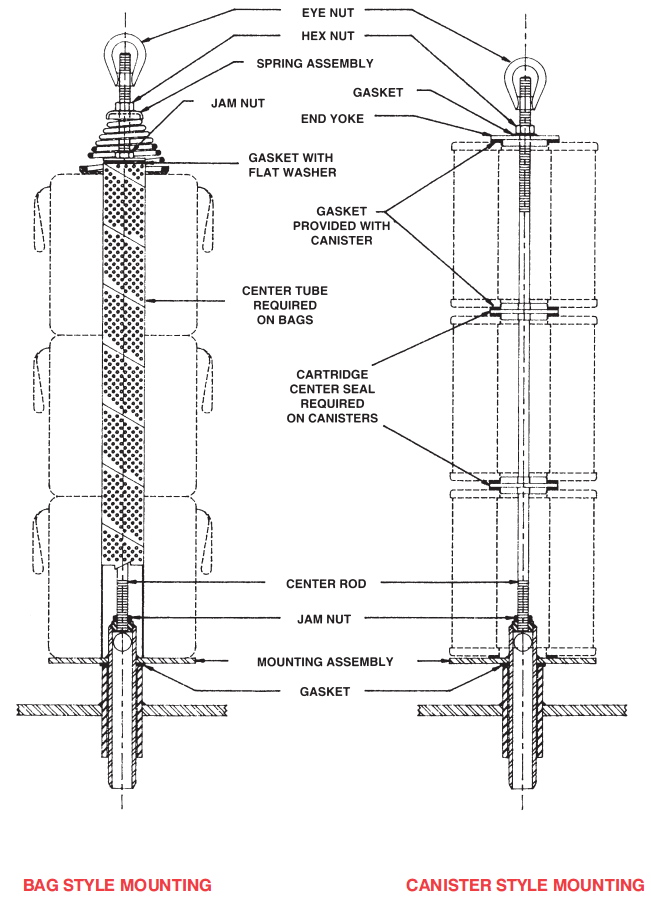

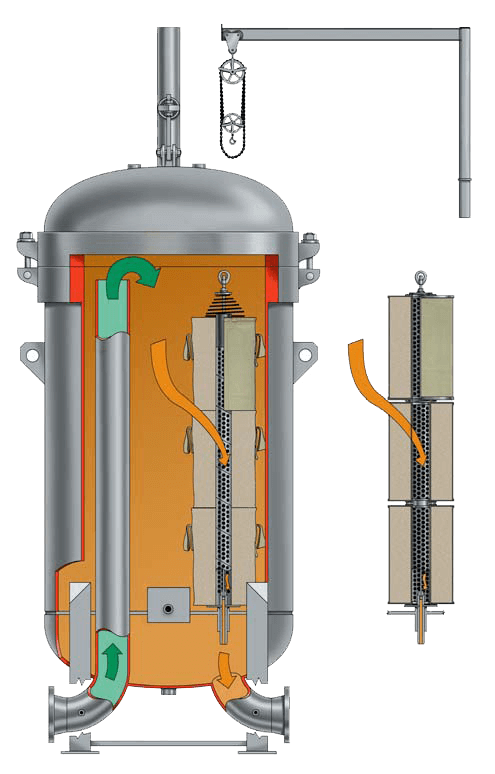

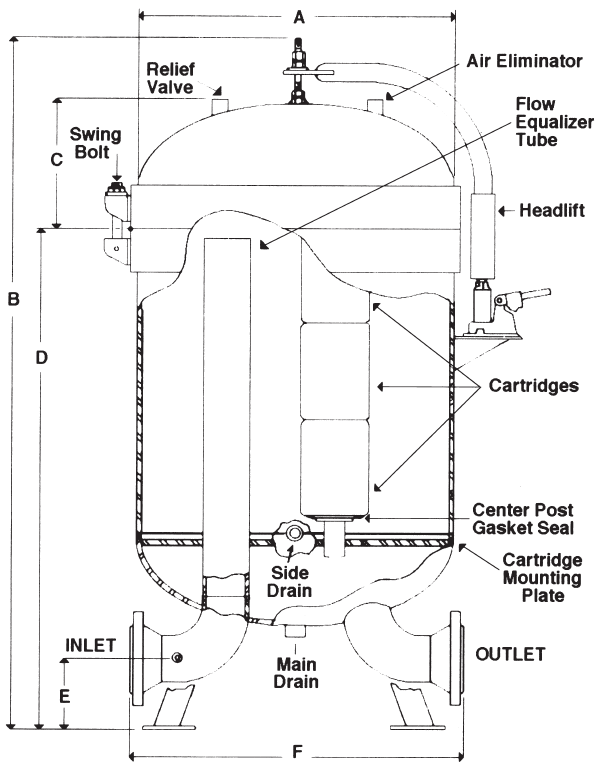

Clay Treaters General Description Clay Treater Cartridges Mounting Arrangments- Welded carbon steel construction

- ASME Code, Section VIII construction, stamped and certified

- Design pressure: 150 psi @ 250°F

- Inlet and outlet permanently marked

- Interior: Epoxy coated

- Exterior: Prime coated

- Removable cartridge mounting post

- Swing bolt closure

- Buna-N closure gasket

- Hydraulic headlift

- Automatic air eliminator

- Differential pressure gauge

- Pressure relief valve

- Sampling probe

- Cartridge hoist assembly

- Working platform, ladder and handrails on 42" (1067 mm) OD and larger housings

- Removable bundle design