The primary purpose of clay treatment is to protect aviation fuel filtration systems and jet fuel by removing trace quantities of surface active agents (surfactants), color, and additives commonly found in fuel.

The attapulgus clay used in these cartridges greatly resists water saturation and provides maximum surfactant adsorptivity and filtration area found in clay treater cartridges.

Our aviation fuel filters such as these will help you to achieve fuel cleanliness in accordance with standards such as ATA 103 and EI 1581.

If you have any questions about filters for aviation fuel or jet fuel filters, feel free to contact us today.

Materials:

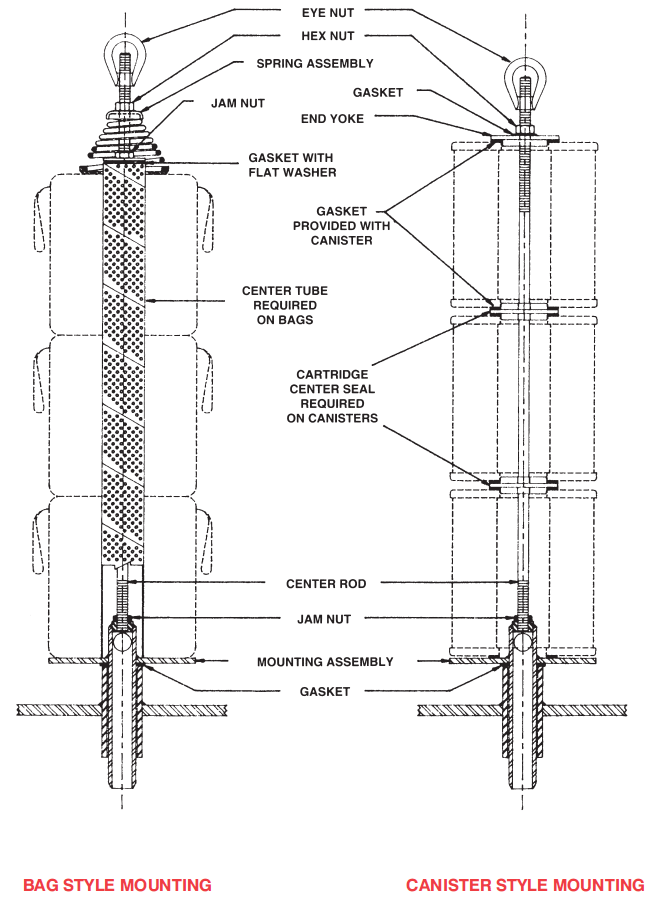

Bag Cartridge

- Polypropylene center tube

- Felt center tube migration barrier

- Tightly woven canvas bag

- Vibra-packed with Attapulgus clay to capacity

- Heavy-duty canvas hoisting handles

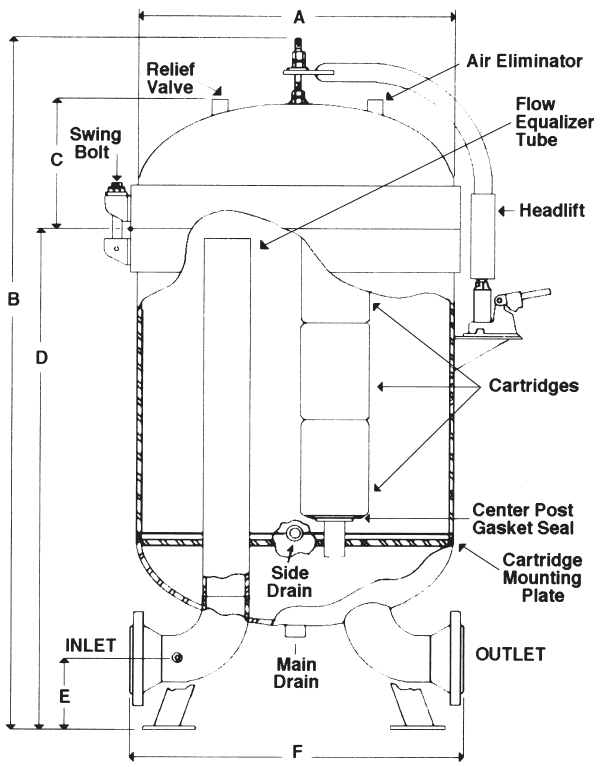

Canister Cartridge

- Perforated metal center tube

- Felt center tube migration barrier

- Non-woven polyester inner wraps

- Vibra-packed with Attapulgus clay to capacity

- Heavy-duty metal hoisting handle

- Coated metal end caps

- Polyester outer wrap

- Buna-N gaskets on both ends for assured sealing

Data:

| Type | Recommended Flow Rate Per Cartridge | Media | Dimensions | Maximum Operating Temperature | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Length | Outside Diameter | Inside Diameter | |||||||||

| GPM | LPM | in. | mm. | in. | mm. | in. | mm. | °F | °C | ||

| Canister | 5-7 | 19-27 | Attapulgus clay, low volatile material, Graded 60-90 mesh | 18 | 460 | 7 | 177 | 2-1/4 | 57 | 240 | 115 |

| Bag | 5-7 | 19-27 | 18 | 460 | 7 | 177 | 2-1/4 | 57 | 140 | 60 | |

| Bag | 5-7 | 19-27 | 19 | 480 | 7 | 177 | 2-1/4 | 57 | 140 | 60 | |

Downloads

Clay Data Clay Treater Cartridges Mounting Arrangments Clay Treater Cartridges- Maximum adsorptive and filtration area

- Greatly resists water saturation

- Vibra-packed clay minimizes settling

- Interchangeable with other manufacturer’s bag and canister clay treater cartridges

- Hoisting handles expedite cartridge installation and changeout

- Flow direction: Outside to in