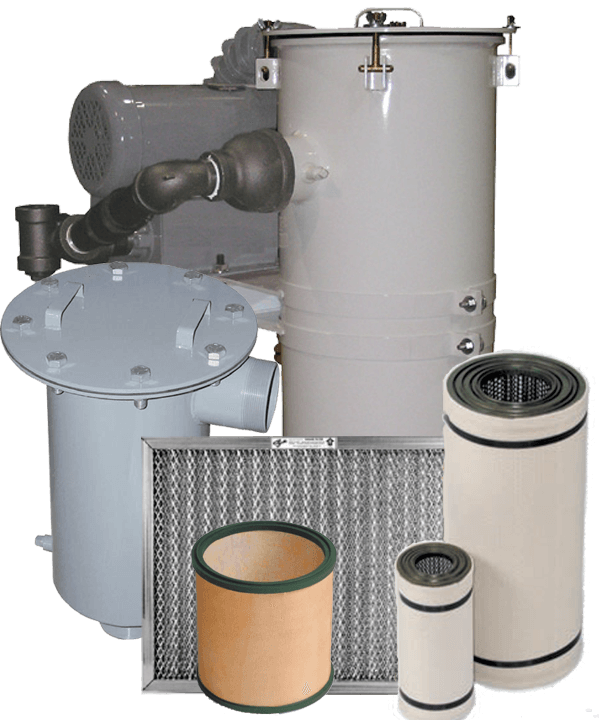

Mist eliminators remove visible oil vapor from the air stream of vents in lubricating oil systems of large, high-speed rotating equipment such as gas turbines, steam turbines, turbo compressors, turbo generators, reciprocating engines, high speed couplings and gear boxes. Mist eliminators prevent oil mist from contaminating air or soil, helping facilities comply with environmental regulations. It also makes for a cleaner, safer work environment by eliminating oily residue build-up on engine room floors, enclosures and stairwells, while improving indoor/outdoor air quality and reducing fire hazards.

Our brands of mist eliminators will save you money by returning oil to the sump that would normally be lost during the venting process, greatly reducing make-up costs. There are variety of mist eliminator types available:

- Vacuum Assisted – designed for systems that cannot withstand back pressure.

- Mist Eliminator with Heat Exchanger – designed for systems where the oil can reach high temperatures (200°F and above)

- Coalescer-Only models – designed for systems where back pressure is not a concern

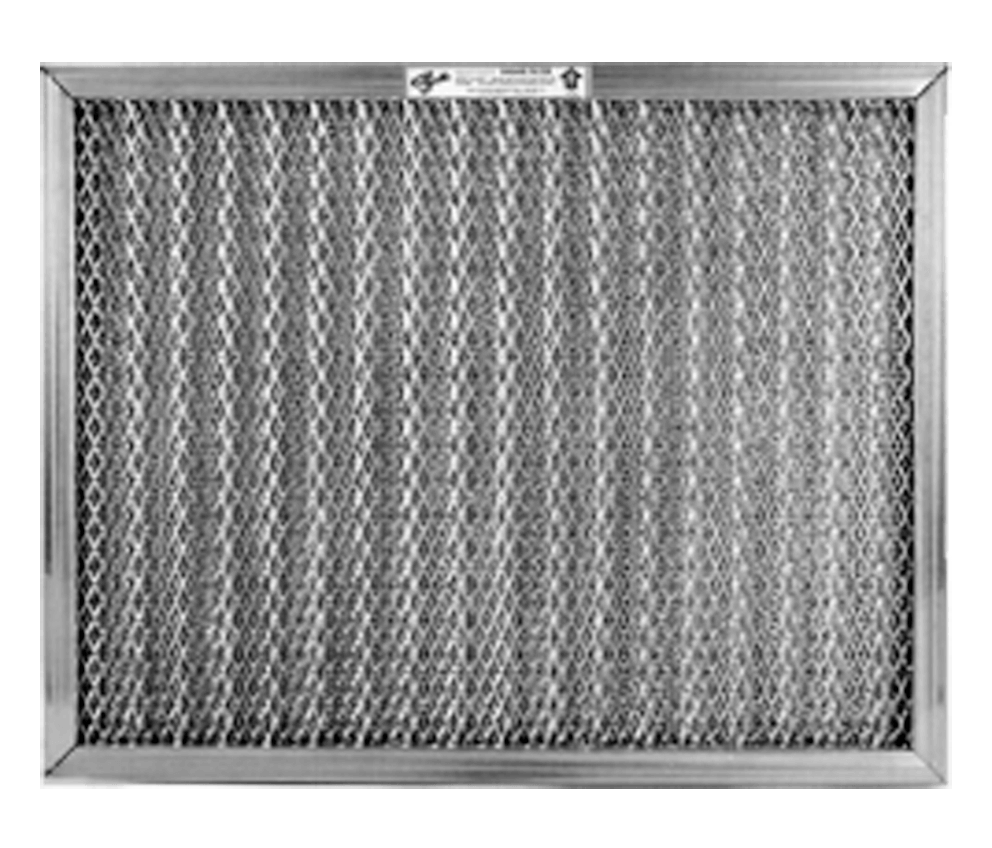

- Mist Eliminating Filter Panels – designed for use in air handling systems

All models eliminate oil mist with an efficiency of 99.97% removal of all airborne contaminant regardless of particle size.

Materials of Construction:

- Enameled Carbon Steel

- 304 Stainless Steel

Applications:

- Gas & Steam Turbine

- Reciprocating Engine & Compressors

- Generators

- Gearboxes

- High Speed Couplings

- Diesel Engines

Downloads

Compact Oil Mist Eliminator Vacuum Assisted Packages Integrated Vacuum Assisted Oil Mist Eliminator Mist Eliminator Filter_Panels Side Exhaust Mist Eliminating Filters- Connection Sizes: 1-1/4” to 24”

- Wide Range of Operating Flows

- All Steel Construction

- Rugged Design – 15 psid @ -20 to 200°F (non-code)

- 304SS Throat Safety Cages Standard

- Carbon Steel leg supports

- Special Finishes

- ∆P Taps, ∆P Gauges

- Other Materials of Construction