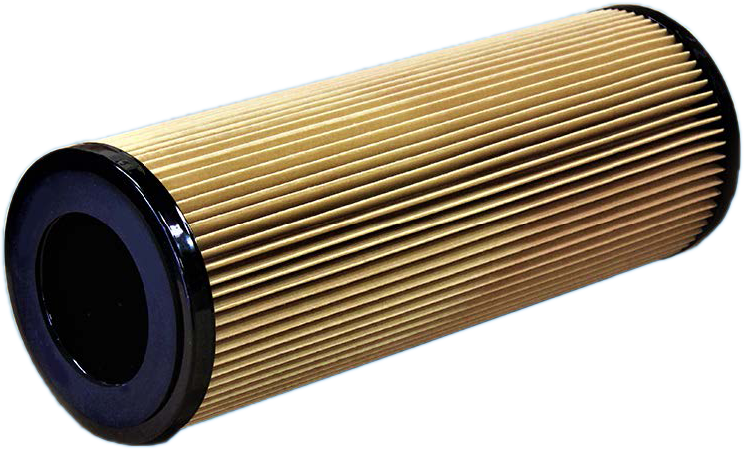

Precision Filtration Products (PFP) Pleated, Synthetic and Teflon separator cartridges are cleanable and reusable separator cartridges of the highest quality in a variety of dimensional configurations. Teflon® coated screen is wrapped around a treated, perforated metal shell, lock-seam folded and secured by metal clips, then adhesive bonded to gasketed metal end caps. The screen is Teflon® coated for more effective water repelling characteristics assuring long, trouble-free service.

PFP’s synthetic separator cartridges feature a specially developed hydrophobic synthetic media which offers all the permanent features of Teflon® screen, with the ability to handle higher flow rates. Synthetic mesh is wrapped around a treated, perforated metal shell, then adhesive-bonded to gasketed metal end caps. The synthetic mesh is designed for more effective water repelling characteristics, assuring long, trouble-free service. The filter separator cartridges pair with the Coalescing Filter Elements are ideal for water removal in Bulk Fuel and Aviation applications. Check out our Coalescer Separator Filter Vessels in our Rental Fleet.

Both types of our filter separator cartridges have a distinctive PFP technology which provides balanced flow of product (radially inward) throughout the cartridge. All metal components are treated to resist corrosion. Maximum recommended operating temperature is 240°F. For compatibility in extreme operating conditions, other gasket, adhesive and metal materials are available.

STANDARD DESIGN FEATURES

- Cleanable and reusable

- Superior water barrier

- Recommended maximum operating temperature: 240°F

- pH range from 5 to 9

- Designed for balanced flow through cartridge

- Flow direction: Outside to inside

MATERIALS

- Synthetic mesh OR Teflon® coated screen

- Treated metal components for corrosion protection

- Buna-N gaskets

- Other gasket, adhesive and metal materials are available on request