Flow Rates: Flow Rates Range from 1 GPM to 22 GPM

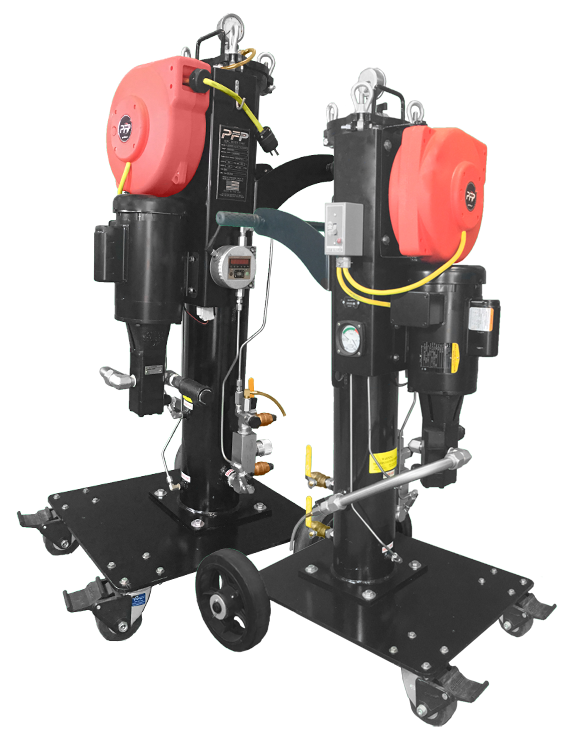

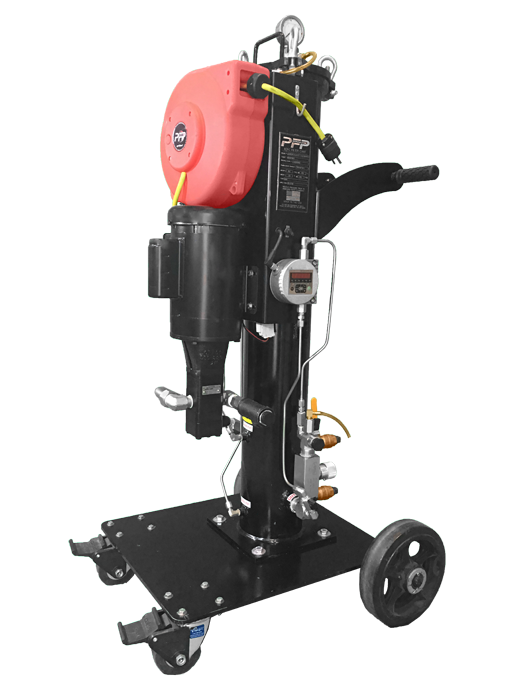

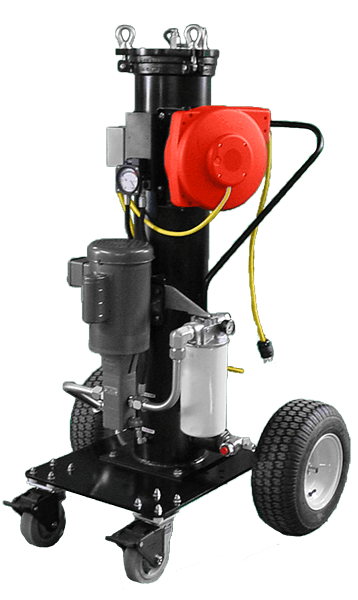

Our LCFC Liquid Cartridge Filter Cart is the ideal filtration system for the recirculating or transferring of fluids in and out of reservoirs and holding tanks. It is ideal for high viscosity lubrication and hydraulic oils.

The LCFC is the perfect filtration unit to use when high levels of particulate contamination are present. The high surface area yields extended service life of the filter elements reducing downtime and filter

change-outs.

The LCFC Filter Cart is manufactured with U.S. made epoxy coated steel. It has large 10” non-shred rubber wheels with swivel/locking casters for ease of portability. All tubing is 304 Stainless Steel for a large compatibility range.

The standard cart is compatible with petroleum and mineral based fluids. For polyol ester, phosphate ester, and other specified synthetics use our Viton seal option or contact factory.

Recommended Viscosity Range*

5 GPM*: 28 SSU ~ 4000 SSU, 6 cSt ~ 800 cSt

11 GPM*: 28 SSU ~ 4000 SSU, 6 cSt ~ 800 cSt

22 GPM*: 28 SSU ~ 2000 SSU, 6 cSt ~ 400 cSt

*At maximum viscosity, clean element pressure drop on 6um Media Please check maximum viscosity of oil in coldest condition.

Downloads

LCFC Filter Cart- BETA 1000 Rated Filter Elements per ISO 16889 Standards

- Water Removal Filter Elements

- Upstream and Downstream Oil Sampling Ports

- Differential Pressure Gauge

- Single or Double Length Element Options

- Condition Bulk Oil Before Use

- ISO Viscosity Range of ISO 22 to ISO 320

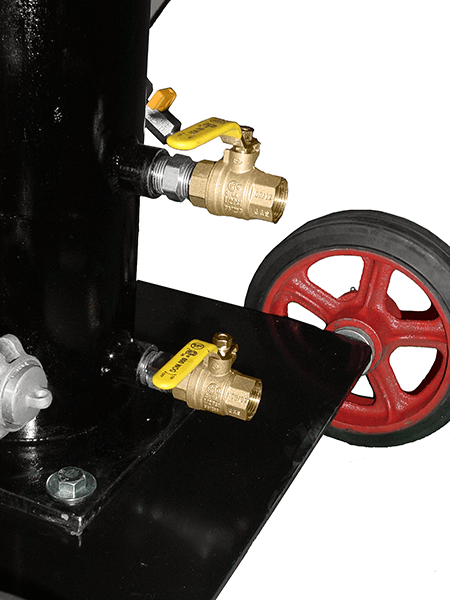

- Seamless Stainless Steel Tubing with JIC Fittings

- Vent Relief Valve with System Pressure Gauge

- (2) Medium Pressure Hydraulic Hoses

- 40-foot Cord Reel

- Flow Rates Range from 1 GPM to 22 GPM

- Electrical Service

- 1Phase/60Hz/115/230V

- 1Phase/50Hz/120/230V

- 3Phase/60Hz/230/460V

- 3Phase/50Hz/380-450V

- Explosion Proof (Class 1)

- Pump Specifications

- Self-Priming Positive Displacement Gear Pump

- Internal Relief Valve Set at 100 PSI

- Motor Options

- Class 1 Explosion Proof

- Pneumatic Pump with Pulsation Dampener

- 50 Hertz, 3 Phase

- Material of Construction

- Assembly Frame: Powder Coated Carbon Steel Platform

- Inlet Suction Strainer for Pump Protection

- Tires: 10” Wheels (Puncture-Resistant)

- Rigid-Locking Swivel Casters

- Filter Housing – Powder Coated, Epoxy Lined, Carbon Steel

- Hoses: Medium Pressure Hydraulic

- Wands: 40” Stainless Steel

- Operating Temperature

- Nitrile (Buna-N): -40F to 150F

- Fluorocarbon (Viton)*: -15F to 200F

- *High Temperature/Phosphate Ester Design

- Hydraulic Oil

- Turbine Oil

- Lubrication Oil

- Gear Oil (ISO VG 220 ~ VG 320)

- Transformer Oil

- Diesel Fuel

- Phosphate Ester (Fyrquel EHC Fluid)

- Filter By-Pass (Transfer Pump)

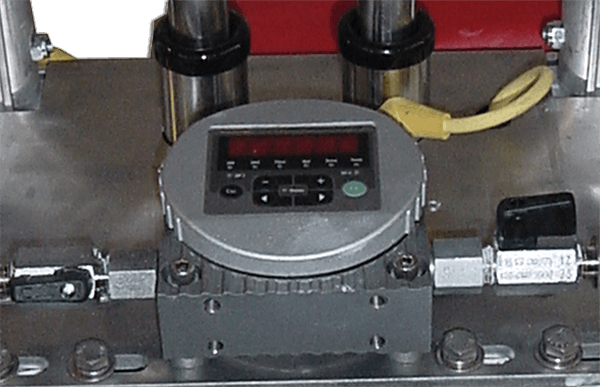

- Inline Digital Particle Counter

- Variable Frequency Drive (VFD)

- Flow Meter

- Spin-On Inlet Strainer

- Reservoir Holding Tank

- Off-Road Wheels

- Custom Colors Available