Contaminants wreak havoc on equipment, ultimately causing machinery to fail and production to stop. Our Breathers prolong equipment life by keeping contaminants out of your equipment. Saving you time and money!

The FACTS…independent studies show, greater than 75% of machine failure is due to avoidable contamination.

Installing a breather will help to increase your efficiency, protect expensive equipment, and reduce maintenance costs. We offer filters designed for a variety of industries and Applications.

Technical Specifications:

- Temp (continuous): min -15° F ( -26° C) max 220° F (104° C)

- Filter change out differential: 10″-15″ in. H2O above initial delta P

- Typical noise attenuation up to 15 dB’s (due to the wide range of applications and machines these units are used on, a single graph is insufficient. Please inquire for your specific requirement)

- Pressure drop graphs available upon request

Applications:

- Compressor-Screw

- Blowers-Side Channel

- Hydraulic Breathers – fine filtration

- Workshop

- Pneumatic Conveying Systems

- Waste Water Aeration

- Nailers/Staplers

- Ash Handling

- 99%+ removal efficiency std: Paper = 2 micron, Polyester = 25 micron

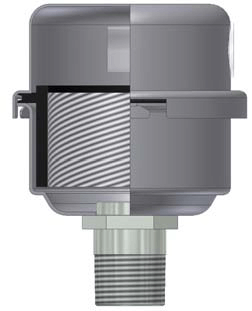

- Fully drawn weatherhood - no welds to rust or vibrate apart

- Tubular silencing design - tube is positioned to maximize attenuation and air flow while minimizing pressure drop

- Durable carbon steel construction with powder coated finish

- Interchangeable elements

- Ability to mount vertically, horizontally