The International Organization for Standardization created the ISO standard 4406 to quantify particulate contamination levels per milliliter of fluid at three diameter sizes: 4µ[c], 6µ[c], and 14µ[c]. This ISO 4406 “cleanliness code” is expressed in 3 numbers: 19/17/14. Each number represents a contaminant level for a correlating particle size. The code includes all particles of the specified size and larger. It is important to note that each time a code increases the quantity range of particles doubles.

Understanding ISO 4406 Cleanliness Codes

When setting target ISO fluid cleanliness codes for hydraulic and lubrication systems it is important to keep in mind the objectives to be achieved. Maximizing equipment reliability and safety, minimizing repair and replacement costs, extending useful fluid life, satisfying warranty requirements, and minimizing production down-time are attainable goals. Once you set a target ISO cleanliness code you should follow a progression of steps to achieve the target, monitor it, and maintain it, which will provide you with many justifiable rewards.

Set the Target

The first step in identifying a target ISO 4406 code for a system is to identify the most sensitive component on an individual system, or the most sensitive component supplied by a central reservoir. If a central reservoir supplies several systems, the overall cleanliness must be maintained, or the most sensitive component must be protected by filtration that cleans the fluid to the target before reaching that component.

| ISO 4406:1999 Code Chart | ||

|---|---|---|

| Range Code | Particles per Milliliter | |

| More than | Up to/Including | |

| 24 | 80000 | 160000 |

| 23 | 40000 | 80000 |

| 22 | 20000 | 40000 |

| 21 | 10000 | 20000 |

| 20 | 5000 | 10000 |

| 19 | 2500 | 5000 |

| 18 | 1300 | 2500 |

| 17 | 640 | 1300 |

| 16 | 320 | 640 |

| 15 | 160 | 320 |

| 14 | 80 | 160 |

| 13 | 40 | 80 |

| 12 | 20 | 40 |

| 11 | 10 | 20 |

| 10 | 5 | 10 |

| 9 | 2.5 | 5 |

| 8 | 1.3 | 2.5 |

| 7 | 0.64 | 1.3 |

| 6 | 0.32 | 0.64 |

Best Practices to Achieve Your Target ISO Cleanliness Code

Step 1: Perform an Oil Analysis

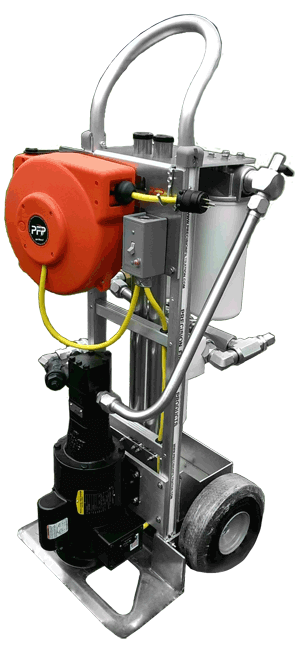

Directly connecting an on-line particle counter, such as this Portable Oil Diagnostic System (PODS), to the hydraulic fluid or lube oil system through sampling ports provides the most accurate snapshot of oil cleanliness and eliminates many of the inherent variables associated with bottle sampling. Check out our fluid diagnostic equipment for more information.

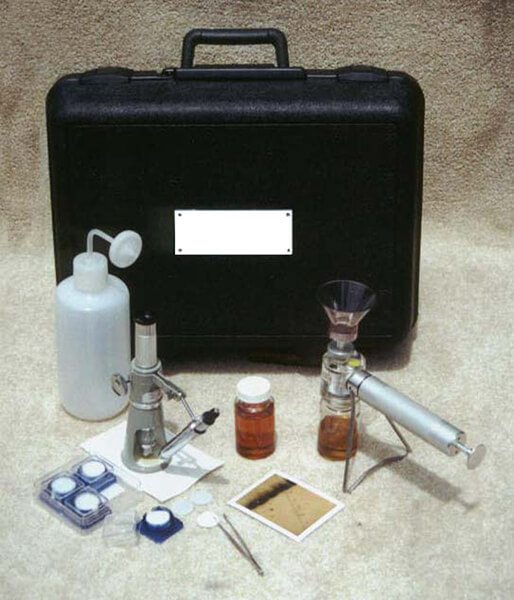

Another option, is to utilize an Oil Analysis Patch Test Kit. This oil analysis test kit is a great complement to the on-line particle counter as it provides the capability to visually analyze oil contamination levels and types in the system.

You can also take a bottle sample and send it out for analysis. If interested, please contact regarding our Oil Analysis Bottle Sample Program.

Step 2: Implement a Filtration System

Once you have determined your current Oil Quality, it is time to implement a filtration system to will best fit your needs. We offer a variety of filtration equipment for every application from Dedicated Filter Panels to Portable Filter Carts. Give us a call to discuss the best option available to meet your needs.

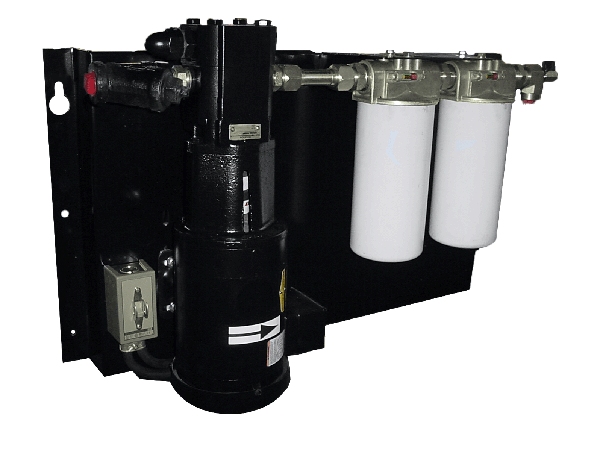

- Dedicated Filter Panel System: We offer dedicated panels with spin-on filters, which are most effective for in-line conditioning of fluids that are already in service. A dedicated filter panel will remove particulate and water contamination.

- Portable Filter Carts & Mobile Filtration Systems: Working inside an industrial plant? Transferring between applications? You NEED a portable filter cart! They are versatile and reliable. A mobile filter cart can be used to remove particulate and/or water from hydraulic fluids, condition turbine and insulating oil, resolve oil refinery upset conditions, clean up hydraulic reservoirs, upgrade filtration systems, filter lube oils, flush and/or change gearbox oil, transfer new fluids, coalesce and separate contaminants from liquid, and to reuse oil and coolants. You can provide us with specifications for a completely custom mobile filtration system in order to meet the needs of your specific application. Our portable filter systems can handle flow rates as low as 0.5 GPM and the higher capacity flow rates (e.g. 5 GPM, 10 GPM, 22 GPM) required for many industrial applications. Each unit is available in a large variety of design options, including stainless steel material and explosion-proof construction!

- Drum-Top Filter Unit: Do you already have a barrel with contaminated oil or hydraulic fluid? Then you NEED this simple barrel-mounted filter unit that fits securely on top of a 55-gallon drum. It is constructed of powder-coated steel and is ideal for filtering and recirculating or transferring in/out of barrels. It includes sampling ports at the inlet and outlet connections to facilitate ISO 4406 cleanliness code comparisons. This drum-top filter unit is ideal for high-viscosity lube oil or any hydraulic oil. It also incorporates a two-stage filtration system that removes both particulate and water contamination.

Step 3: Establish an Oil Quality Program

Establish an Oil Quality Program to prolong the life of your most critical components, thus decreasing your downtime and saving you money.