Flow Rates: 1, 5, 11, 22 GPM

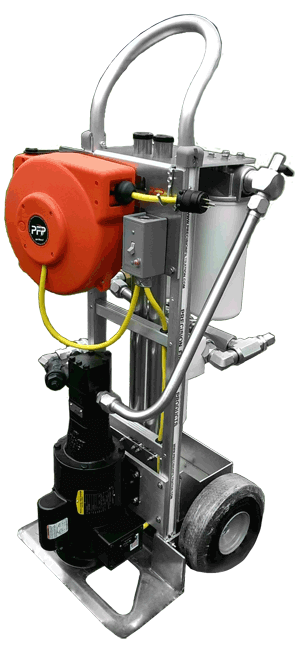

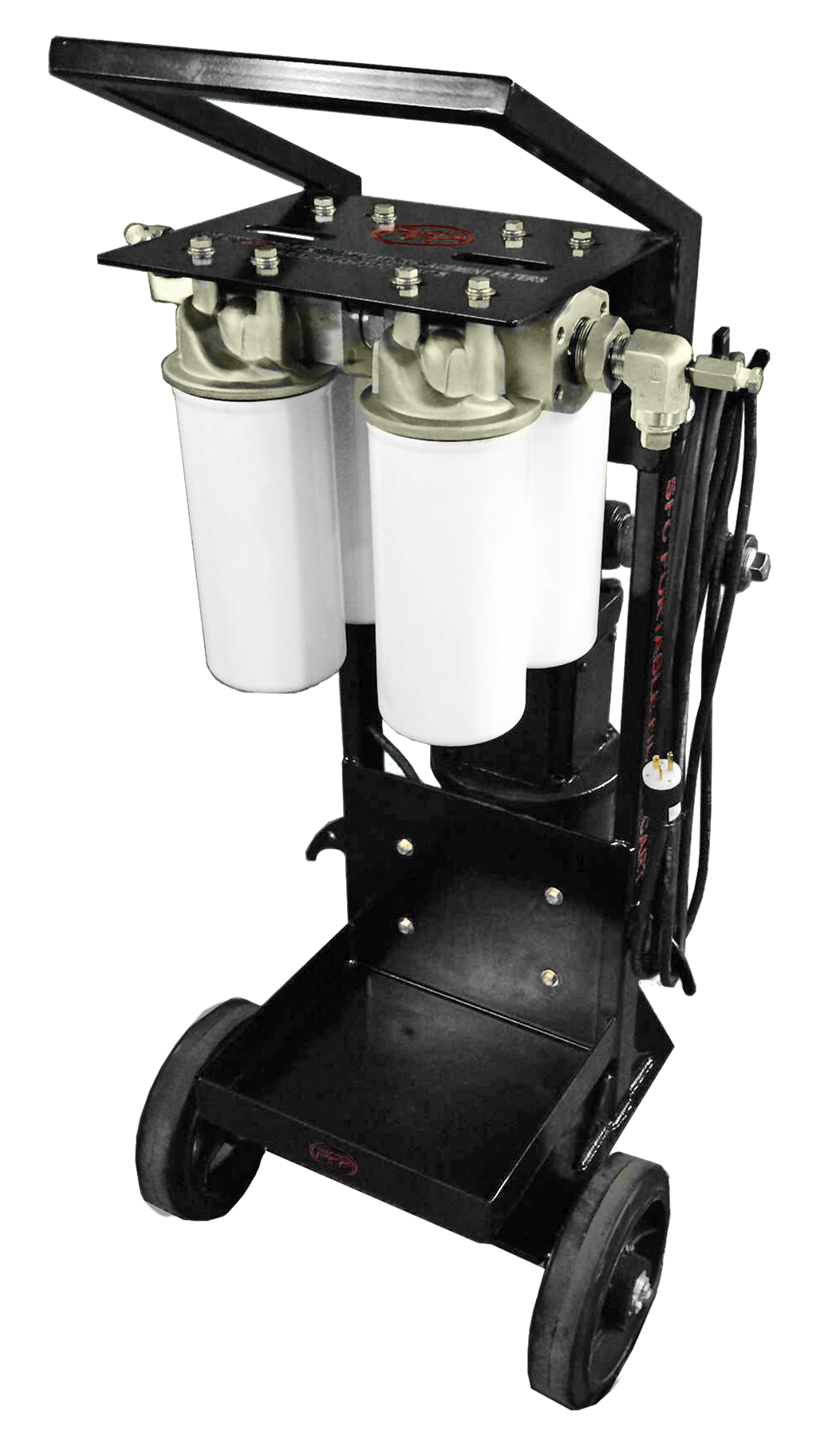

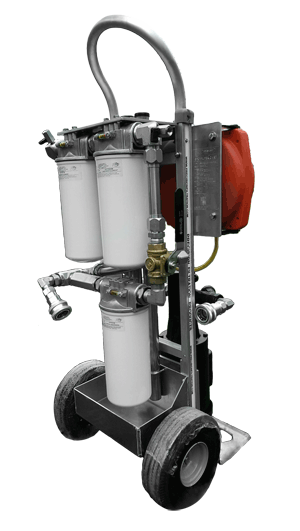

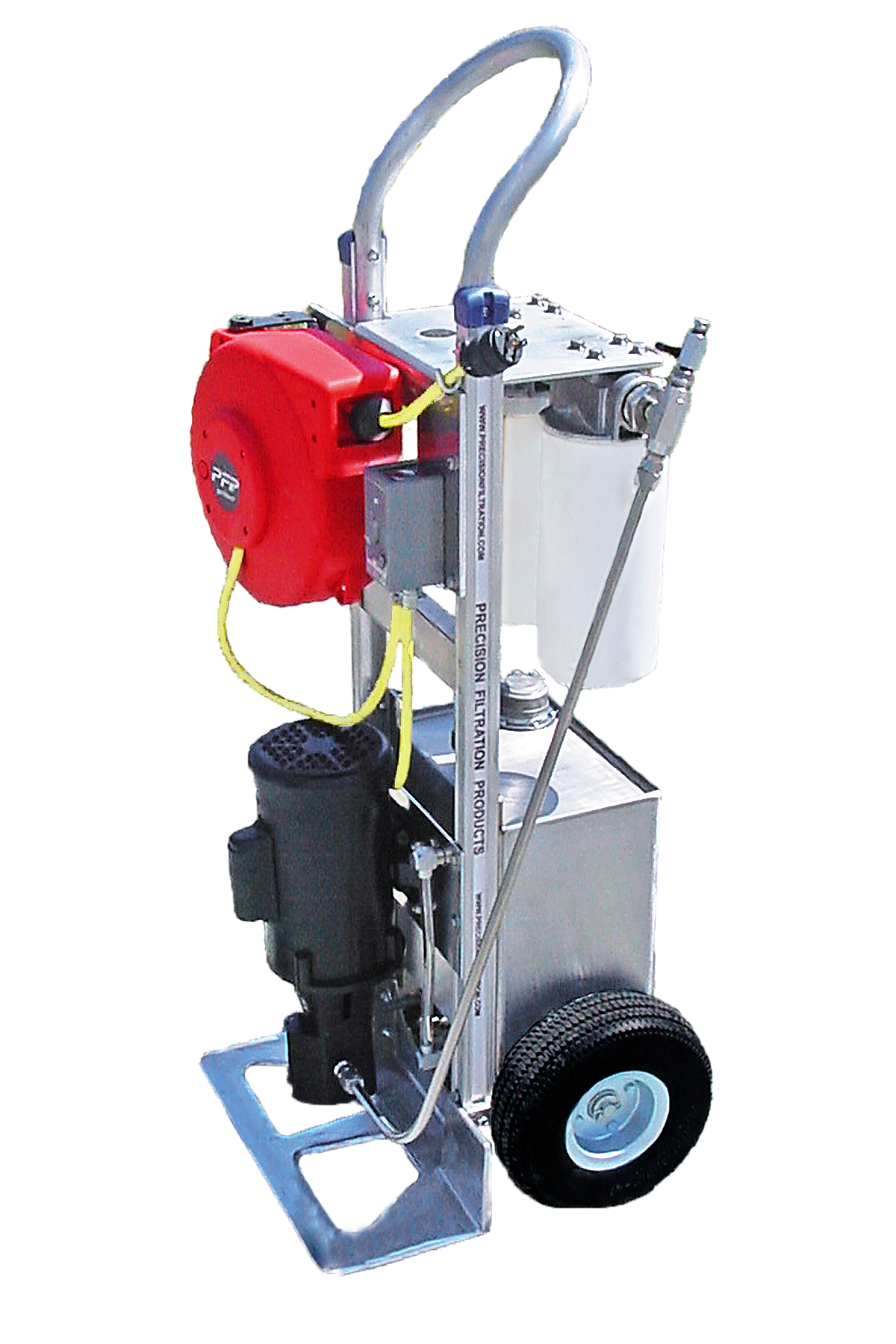

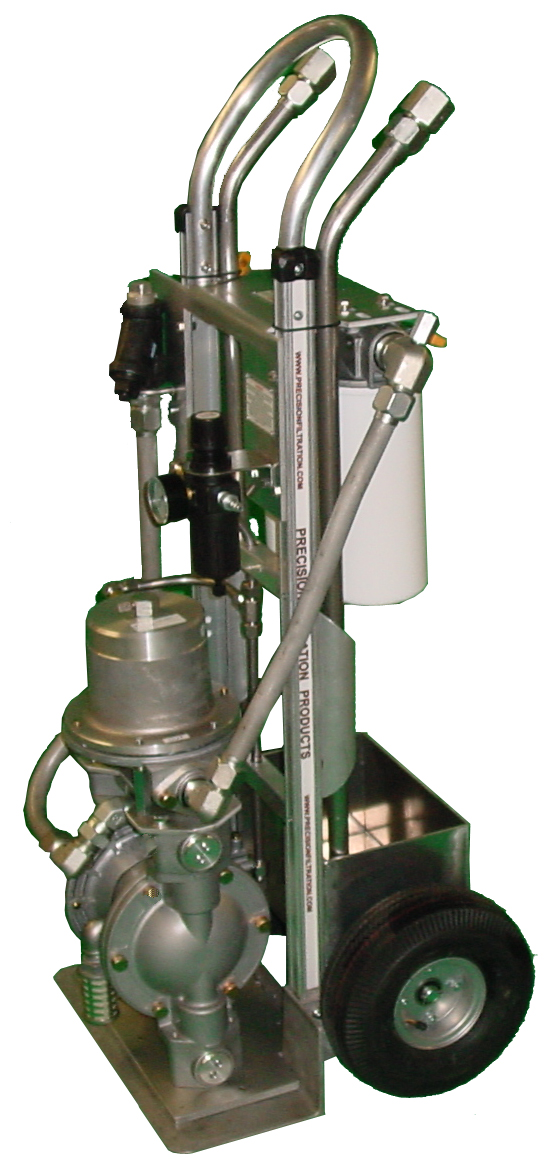

Our SFC Spin-On Filter Cart is ideal for hydraulic fluids (ISO VG 22 ~ ISO VG 68). The two stage filtration offers the advantage of removing both particulate and water contamination. It is designed for filtering new fluids during transfer and replenishment, flushing fluids already in service, removing particulate and water contamination, and conditioning bulk oil before use. It is also available with an on-board particle counter and 3-Stage By-Pass option.

The SFC Filter Cart is constructed with a strong, lightweight aluminum cart with puncture-resistant tires. It is available with Beta 1000 rated Microglass and Water Absorbing filter elements. It also includes oil sampling ports on the inlet and outlet connections to provide ISO 4406 code comparisons. This will allow you to meet your target cleanliness codes and prolong the life of your equipment and fluids.

New oil is clean? On average new oil delivered from a drum has a cleanliness level of ISO 4406 cleanliness code of 22/21/19. Water content from new oil averages 200 to 300 PPM.

The SFC Filter Cart is available with a Mechanical Pump and Motor combination as a standard. A Pneumatic Pump with Pulsation Dampener is available as an option, as well as an explosion-proof version. Contact us or your sales representative for additional information.

Downloads

SFC Spin-On Filter Cart- BETA 1000 Rated Filter Elements per ISO 16889 Standards

- Water Removal Filter Elements

- Upstream and Downstream Oil Sampling Ports

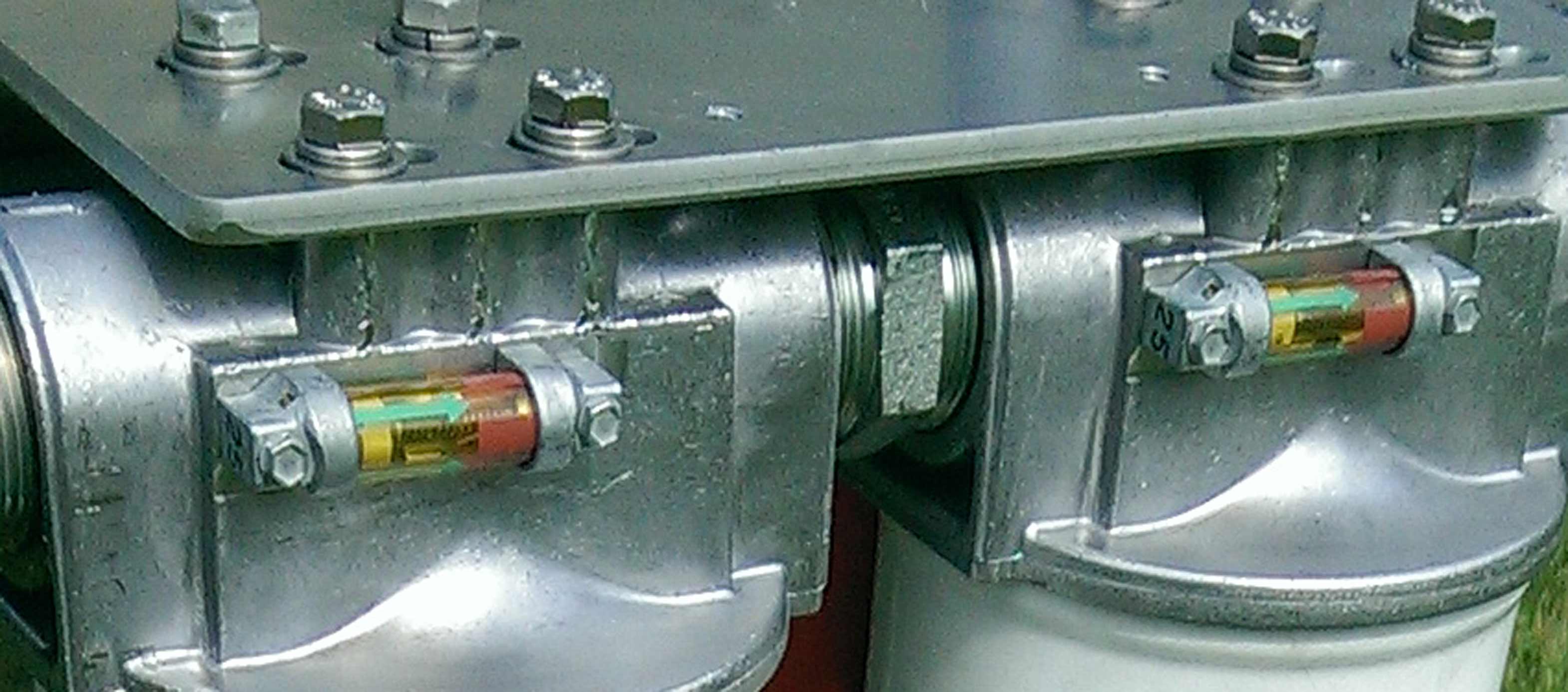

- True Differential Indicators

- 25 PSID By-pass

- ISO Viscosity Range of ISO 22 to ISO 320

- Seamless Stainless Steel Tubing with JIC Fittings

- Flow Rates Range from 1 GPM to 22 GPM

- Electrical Service

- 1Phase/60Hz/115/230V

- 1Phase/50Hz/120/230V

- 3Phase/60Hz/230/460V

- 3Phase/50Hz/380-450V

- Explosion Proof (Class 1)

- Pump Specifications

- Self-Priming Positive Displacement Gear Pump

- Internal Relief Valve Set at 100 PSI

- Motor Options

- Class 1 Explosion Proof

- Pneumatic Pump with Pulsation Dampener

- 50 Hertz, 3 Phase

- Material of Construction

- Assembly Frame: Lightweight Aluminum

- Inlet Suction Strainer for Pump Protection

- Tires: 10” Pneumatic (Puncture-Resistant)

- Filter Assembly: Aluminum Head, Steel Canister

- Hoses: Medium Pressure Hydraulic

- Wands: 40” Stainless Steel

- Operating Temperature

- Nitrile (Buna-N): -40F to 150F

- Fluorocarbon (Viton)*: -15F to 200F

- *High Temperature/Phosphate Ester Design

- Hydraulic Oil

- Turbine Oil

- Lubrication Oil

- Gear Oil (ISO VG 220 ~ VG 320)

- Transformer Oil

- Diesel Fuel

- Phosphate Ester (Fyrquel EHC Fluid)

- Filter By-Pass (Transfer Pump)

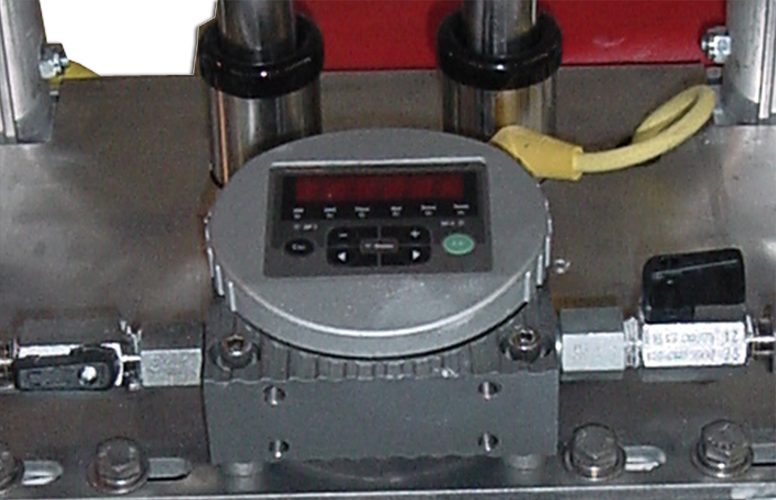

- Inline Digital Particle Counter

- Variable Frequency Drive (VFD)

- Flow Meter

- 3rd Stage Optional By-Pass

- Spin-On Inlet Strainer

- Reservoir Holding Tank

- NEMA 7 (explosion-proof enclosure)