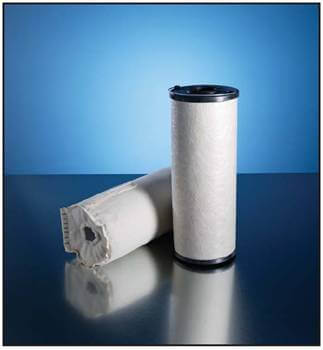

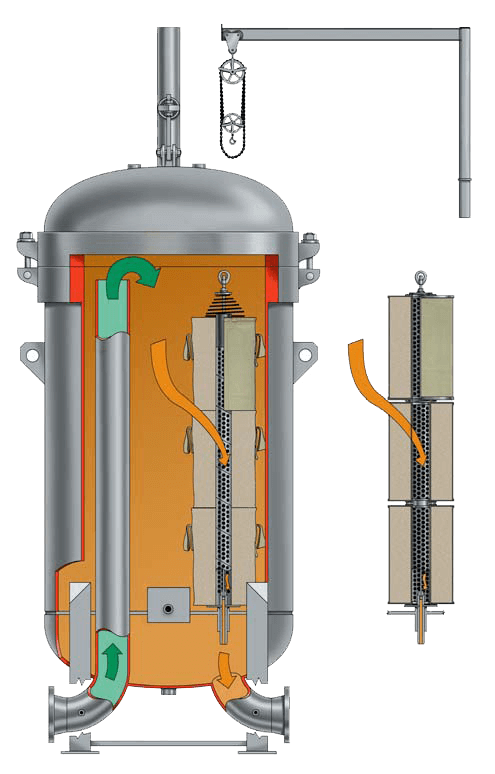

Clay Treaters are used in multiproduct pipeline installations, and wherever surfactant laden or discolored fuel is a problem. They can be configured to accept bags or canisters.

Clay treaters will continuously adsorb surfactants, color and additives from jet fuel when used with Facet replaceable clay elements. Housings are designed for easy servicing and low maintenance. All are built to ASME Code, Section VIII. Standard and optional accessories and connections are available to facilitate piping and installation requirements.

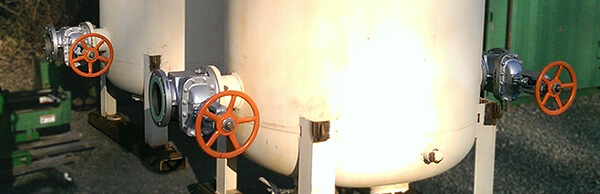

PFPUSA has one of the largest Clay Treater Rental Fleets in the country. We can utilize a single Clay Treater or manifold multiple Clay Treaters together to achieve your desired flow rate and maximize the residence time required to properly clean your fuel from a variety of problems.

On average, we are able to treat your fuel for around $0.05 a gallon. What does it cost to down grade it?

Materials of Construction

Carbon Steel

Interior – Epoxy Coated

Exterior – Prime Coated

Clay Treater Inventory

(Please note, we are continually adding to our fleet. If you don’t see what you need here, give us a call with you requirements and we help you determine the best possible equipment required to solve your problem.)

| Model #: | Description: |

|---|---|

| CTC-001 | Kerosene Clay Filter Vessel, 6”-150# Flanges; 150-PSIG Design Pressure @ 200°F, Hydro Test @ 225 PSIG, Change-Out @ 20 PSID, 800 GPM; Accepts 120 Clay Canisters |

| CTC-002 | Kerosene Clay Filter Vessel, 6”-150# Flanges; 150-PSIG Design Pressure @ 200°F, Hydro Test @ 225 PSIG, Change-Out @ 15 PSID, 465 GPM; Accepts 72 Clay Canisters |

| CTC-003 | Kerosene Clay Filter Vessel, 6”-150# Flanges; 150-PSIG Design Pressure @ 200°F, Hydro Test @ 225 PSIG, Change-Out @ 20 PSID, 800 GPM; Accepts 120 Clay Canisters |

| CTC-004 | Kerosene Clay Filter Vessel, 6”-150# Flanges; 150-PSIG Design Pressure @ 200°F, Hydro Test @ 225 PSIG, Change-Out @ 20 PSID, 800 GPM; Accepts 120 Clay Canisters |

| CTC-005 | Kerosene Clay Filter Vessel, 6”-150# Flanges; 150-PSIG Design Pressure @ 200°F, Hydro Test @ 225 PSIG, Change-Out @ 20 PSID, 800 GPM; Accepts 120 Clay Canisters |

| CTC-006 | Screen-Shot-2017-08-09-at-1.25.49-PM.png Screen-Shot-2017-08-09-at-1.25.49-PM.png 100% 10 Kerosene Clay Filter Vessel, 6”-150# Flanges; 150-PSIG Design Pressure @ 200°F, Hydro Test @ 225 PSIG, Change-Out @ 20 PSID, 800 GPM; Accepts 120 Clay Canisters Screen reader support enabled. Kerosene Clay Filter Vessel, 6”-150# Flanges; 150-PSIG Design Pressure @ 200°F, Hydro Test @ 225 PSIG, Change-Out @ 20 PSID, 800 GPM; Accepts 120 Clay Canisters |

| CTC-007 | Kerosene Clay Filter Vessel, 6”-150# Flanges; 150-PSIG Design Pressure @ 200°F, Hydro Test @ 225 PSIG, Change-Out @ 20 PSID, 800 GPM; Accepts 120 Clay Canisters |

| CTC-008 | Kerosene Clay Filter Vessel, 8”-150# Flanges; 150-PSIG Design Pressure @ 200°F, Hydro Test @ 225 PSIG, Change-Out @ 20 PSID, 1000 GPM; Accepts 150 Clay Canisters |

| CTC-009 | Kerosene Clay Filter Vessel, 6”-150# Flanges; 150-PSIG Design Pressure @ 200°F, Hydro Test @ 225 PSIG, Change-Out @ 15 PSID, 800 GPM; Accepts 72 Clay Canisters |

Downloads

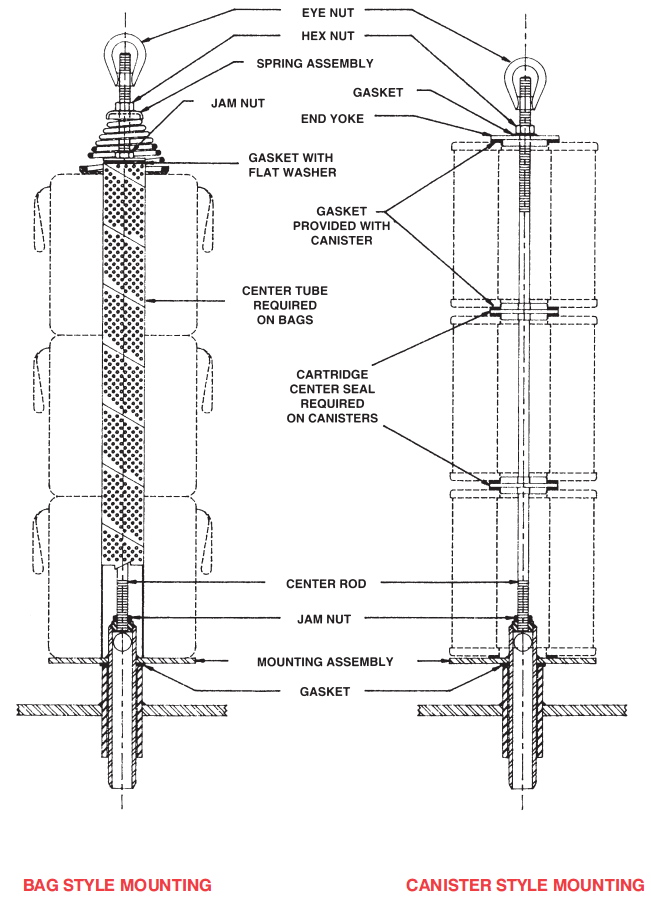

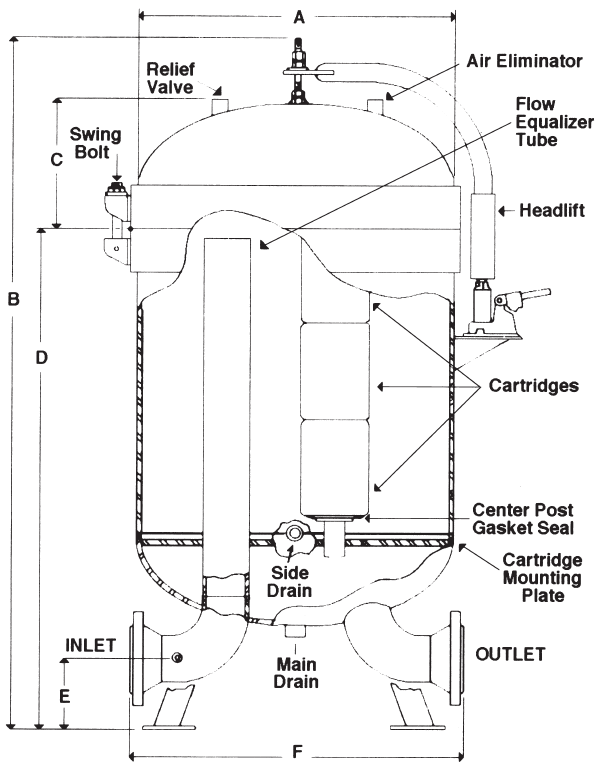

Clay Treaters General Description Clay Treater Cartridges Mounting Arrangments- Welded carbon steel construction

- ASME Code, Section VIII construction, stamped and certified

- Design pressure: 150 psi @ 250°F

- Manual Vent Relief

- Bottom Drains with Cam and Groove Connections for easy vac downs

- Dial Pressure Gauges on Inlet and Outlet

- Sample Ports on Outlet

- Swing bolt closure

- Buna-N closure gasket

- Automatic air eliminator

- Differential pressure gauge

- Pressure relief valve

- Sampling probe

We can supply you with the temporary Cargo Hose, Gate Valves, Tees, Elbows, Pump, Portable Containment, and many more to provide you a complete turnkey set up. We have service crews available to set up, monitor, and breakdown the temporary systems as well.

Give us a call to discuss your application….888-679-6645!