Earlier this year a production manager at a distillery contacted us. They produce alcoholic spirits, including vodka in this particular application.

In order to address the quality of the vodka the customer was measuring the turbidity of it. If you are not familiar with turbidity, it is a measure of the degree to which a liquid loses its transparency due to the presence of suspended particulates. The more total suspended solids in the liquid, the murkier it seems and the higher the turbidity. Turbidity is considered as a good measure of the quality of the liquid.

Here was some of the initial information we were provided about the goals of filtration:

- Most extreme applications: Filtering from about 50 NTU to <1 NTU

- Most applications from about 10 NTU to <1 NTU

- All of their products to be < 1NTU

In order to address the suspended particles we selected a microfiber-glass pleated filter cartridge with polypropylene hardware. These are high surface area pleated cartridges that will extend the life of the filter and not require a significant # of filter change-outs for those large batches of vodka. (See Cut sheet attached for more information) We targeted using 3 different cartridges to address the NTU levels. They were:

- 0.45 Micron

- 1 Micron

- 3 Micron

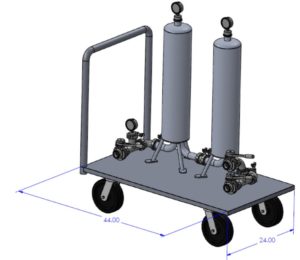

The customer was looking to polish 1,000 gallon batches throughout their distillery so we wanted to put together a custom mobile filtration cart that the customer could move from batch to batch and connect and disconnect the unit with ease.

Since we were working with a food and beverage application we needed to integrate fully sanitary system that included all stainless steel fittings. For our system we decided on Tri-Clamp Sanitary Fittings in combination with Teflon gaskets which are particularly used as Brewery Fittings by Wineries and Breweries. These polished fittings are excellent what you need to make a Sanitary Connection that is secure, easy to clean and leak proof. Below is a drawing of the Mobile Dual Stage Set-Up we proposed:

The cart we provided had (2) 316 Stainless Steel housings on it that hold (3) 20” long cartridges each. These were mounted to a stainless Platform Cart and 8×2 Casters and a Stainless Steel Handle. We also left a little extra room for the customer to install their own existing stainless steel double diaphragm pneumatic pump.

Below is a final photo before it shipped out:

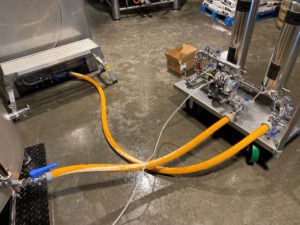

Once the customer received the system they were able mount the pump on the cart and install it within a week. They gave us immediate feedback that the system was working great Take a look at the final setup!

Left: Filtration by-pass outlet/filter air purge, Center: Inlet/Infed from batch, Right: Filter outlet

The customer had success filtering 500 gallons of their Strawberry Vodka from 4.5 NTU to 1.8 NTU using the 3micron in the first stage and .45micron in the second stage. They ran our pump as fast as we were comfortable with and never exceeded 4psi in the chambers, so the flow rate is exceptional and they will see extended filter life.

Feel free to give us a call if you need any help addressing your product quality at your local winery, brewery or distillery!

Another successful filtration venture. Questions or comments? Feel free to reach out to us.

Cheers!

— Sean @ PFP (also thanks to John and Karl)