On behalf of the engineering department at PFP, I would like to share with you one of our latest fabrications, the BSPC, or Bulk Storage Platform Cart.

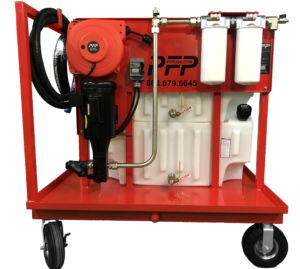

As you can appreciate from the photo, this unit is a platform-mounted filter cart with a built-in reservoir. The platform as you can see is a powder-coated red carbon-steel platform with spill containment lip, push rail, two swivel casters, and two rigid casters.

As you can appreciate from the photo, this unit is a platform-mounted filter cart with a built-in reservoir. The platform as you can see is a powder-coated red carbon-steel platform with spill containment lip, push rail, two swivel casters, and two rigid casters.

This particular filter cart is used for filtering fluids that need an intermediary storage tank/reservoir, such as when you need to transport a larger quantity of oil from bulk storage to the shop or plant area.

We designed the BSPC to deliver single or dual oil types to their final destination. It can filter either mineral oil or synthetic based oils, including hydraulic oil, gear oil, and turbine oil. It can handle such oils with viscosities up to 600 cSt (ISO VG 680) at 100°F within ambient temperatures ranging from -15°F to 150°F. The BSPC is ideal for pre-filtering new oil, transferring oils, top-offs, dispensing new oil, or even for waste oil extraction.

The system shown in the photo includes two 32-gallon stackable polypropylene tanks. Each tank has ball valves on the outlets, fill ports and moisture and particulate preventative breathers.

We offer this model at the following flow rates:

- 1 GPM

- 5 GPM

- 11 GPM

The particular unit shown in the photo above runs at 5 GPM, and we currently offer the following tank sizes:

- 32 gallons

- 71 gallons

- 115 gallons

The system comes standard with a Cast Iron External Gear Pump with a Viton Mechanical Seal that is mounted to TEFC Baldor motor. The electrical configuration of the motor can be wired to any electrical configuration required. In this set-up the motor is powered by a NEMA-4 enclosed manual motor switch that is wired to a 40-foot retractable cord reel.

Each spin-on filter head includes a slide bar indicator that provides you with a visual color coded gauge indicating when to change the filter. The head will accept a pleated micro glass spin-on filter typically designed for up to 25-PSI differential pressure. These high-efficiency microglass filters that are Beta(c)>1000 per ISO 16889, meaning that 99.9% of the particles will be removed in multi-pass at the specified micron level. This will enable you to quickly and reliably achieve very low particle counts to meet or exceed your target ISO 4406 cleanliness level.

Do you have any questions about oil filtration or mobile filter carts? Feel free to contact us and ask to speak with me.

— Sean @ Engineering & Sales, PFP