Many people have asked about our custom-made drum-top filter unit. Why did we make it? What’s the story behind it? How did we create it? Well, it all started when I contacted John, the managing service engineer at a large wind farm located in the mid-west. In order to top off their oil reservoirs, they were using home-made hand pumps to transfer their hydraulic lubricant to oil-safe totes. Every time they opened a barrel to prepare for a turbine gearbox oil flush (or daily needs) the oil would get exposed to the atmosphere. Dust and moisture from the ambient air was contaminating the lube oil, thus reducing the service life and reliability of both the gearbox and the inline filters.

Many people have asked about our custom-made drum-top filter unit. Why did we make it? What’s the story behind it? How did we create it? Well, it all started when I contacted John, the managing service engineer at a large wind farm located in the mid-west. In order to top off their oil reservoirs, they were using home-made hand pumps to transfer their hydraulic lubricant to oil-safe totes. Every time they opened a barrel to prepare for a turbine gearbox oil flush (or daily needs) the oil would get exposed to the atmosphere. Dust and moisture from the ambient air was contaminating the lube oil, thus reducing the service life and reliability of both the gearbox and the inline filters.

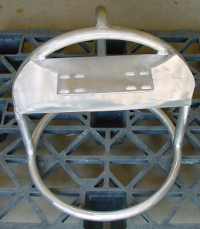

I wanted to help them out quickly, so I contacted one of our vendors who provided hydraulic oil filtration products for wind turbines. Unfortunately, their system, which happened to be made in China, had a very high center of gravity and a narrow base. This caused it to get off balance when it was placed on top of a barrel, which gave it a high potential of tipping over and causing oil spills and/or injuries to operators. Since we identified poor quality in the supplier’s product, we decided to custom-manufacture a new and improved oil barrel-top filtration unit on our own. After our engineers brainstormed how to improve its features and quality, we designed a quick mock-up out of cardboard. After about a month of rigorous analysis and testing we had created a full-size prototype unit with an aluminum frame, which we made sure included a pump and motor made in the U.S.A. We then had our manufacturing team get to work.

I wanted to help them out quickly, so I contacted one of our vendors who provided hydraulic oil filtration products for wind turbines. Unfortunately, their system, which happened to be made in China, had a very high center of gravity and a narrow base. This caused it to get off balance when it was placed on top of a barrel, which gave it a high potential of tipping over and causing oil spills and/or injuries to operators. Since we identified poor quality in the supplier’s product, we decided to custom-manufacture a new and improved oil barrel-top filtration unit on our own. After our engineers brainstormed how to improve its features and quality, we designed a quick mock-up out of cardboard. After about a month of rigorous analysis and testing we had created a full-size prototype unit with an aluminum frame, which we made sure included a pump and motor made in the U.S.A. We then had our manufacturing team get to work.

After we produced the initial prototypes, we revised the original frame and improved the system even more so that it was better protected during transport. We also balanced the weight distribution even further so that it would sit even more securely on oil barrels. Of course we made sure to include filter media that removes both particulate and water contamination. We also added an adapter kit to seal the drum (acting like a reservoir) from outside contamination and thus allow the operator to filter the oil while transfering the fluid at the same time. After manufacturing a steel-frame version of the unit, I had it shipped to John and his wind turbine service team. They were very pleased with the results that it provided, and now all new wind farms at his company have the drum-top filter system specified in their list of build materials. We have received reports that the systems are working flawlessly to filter and transfer the gearbox lubrication oil for their wind turbines.

After we produced the initial prototypes, we revised the original frame and improved the system even more so that it was better protected during transport. We also balanced the weight distribution even further so that it would sit even more securely on oil barrels. Of course we made sure to include filter media that removes both particulate and water contamination. We also added an adapter kit to seal the drum (acting like a reservoir) from outside contamination and thus allow the operator to filter the oil while transfering the fluid at the same time. After manufacturing a steel-frame version of the unit, I had it shipped to John and his wind turbine service team. They were very pleased with the results that it provided, and now all new wind farms at his company have the drum-top filter system specified in their list of build materials. We have received reports that the systems are working flawlessly to filter and transfer the gearbox lubrication oil for their wind turbines.

Do you have a question about oil filters or wind turbine filtration? Feel free to contact us anytime. Our friendly team of experts will be happy to help you out with your particular issue.

Until next time!

Paul at Precision Filtration Products

Paul at Precision Filtration Products

P.S. Have you seen our latest videos? If not, click here to check them out now!